Single Origin

We proudly source all of our cocoa from our friends at Kokoa Kamili. That’s right – every bar, nib, chip, and disc we make first got its start on a farm in southwestern Tanzania, where it was carefully plucked, scooped, fermented, dried, packaged, and shipped to our doors.

Organic cocoa beans from Kokoa Kamili on-deck for roasting in Mt Kisco, NY.

We had been in business for only a few years when we first teamed up with Kokoa Kamili. There was a kindred spirit with their aspirations in craft chocolate, and co-founders Simran Bindra and Brian LoBue brought with them a fresh, positive, and genuine energy from the start. In the spirit of true partnership, we’ve weathered both highs and lows together and have emerged more bonded because of them. During an immensely difficult time when we faced ruthless scrutiny in the media and our industry, Kokoa Kamili held strong and outwardly supported us. It meant the world then, and it still does.

Later on, we asked Simran if there were other ways in which we could help Kokoa Kamili. The clarity of his answer struck us: "Buy more beans." We laughed at how simple it sounded. At that moment, we committed to deepening our roots with Kokoa Kamili by exclusively using their cacao for 100% of our chocolate products, instead of purchasing smaller amounts from many regions around the world. We went from having a collection of single origin bars to having a collection of bars from one single origin: Tanzania.

We were grateful to sit down with Simran and reflect on Kokoa Kamili and Mast’s shared past, to discuss Kokoa Kamili’s present work, and to hear what’s in store for their future.

Mast Journal: As you've mentioned, “Kamili” means “exact” in Swahili. Can you talk about why you chose that name and how it applies to your process?

Simran: We wanted a word that would convey our commitment to quality and precision to our customers and our chocolate makers. But if that was the only thing we wanted, we would’ve used an English word, not a Swahili one. We also wanted a word that would convey to our farmers that we would always try to be the best option for them. We wanted them to understand our commitment to service. Commodity trade and agricultural trade has such a history, throughout the world, of the middle men putting a squeeze on the farmers, and the person at the bottom is always the farmer. We also wanted to convey our commitment to ourselves of what we wanted to uphold, meaning: good quality cocoa coming in and good quality cocoa going out, whether that’s one kilo of cocoa or 500 kilos.

Mast Journal: Stepping back a bit, what brought you to Mast initially and how did that relationship form?

Simran: We were seeing this emergence and a new wave of chocolate makers who wanted good quality cocoa and wanted the ethics around sourcing those beans to be something they could stand behind. So we started our first season, we poured our entire savings into the business, we produced 23 or 25 tons of cocoa beans, then we thought, "Great — now we have to find somebody to buy this." We had this container of cocoa sitting in Tanzania, and just started cold-calling chocolate makers. My sister lives in New York and I was visiting her, and I knew I’d wanted to reach out to Mast. I actually think I’d emailed with someone at Mast who had responded to my email, which was atypical at that time. So I just showed up in Brooklyn with a sample of beans and got to talking with them, and they agreed to take our entire first year’s production.

Luckily, they were willing to take a gamble on us. They didn’t know us from Adam, but they were willing to roll the dice and really believed in the farmer-centric side of things. They’re our biggest chocolate-making customer and have been since the first year’s harvest. As a result, we’ve been able to grow our business — right now, we work with 1300 organic certified farmers. At our busiest, we have about 100 people working at our facility, and 98 of them have never had formal employment before. It’s been cool to be able to build this business in a very rural part of the country, to be able to source from as many farmers as we do, and to pay them much higher prices for their cocoa than anyone else in the country.

Mast Journal: I imagine that’s been very rewarding to go from cold-calling chocolate makers to having put Tanzanian cacao on the map.

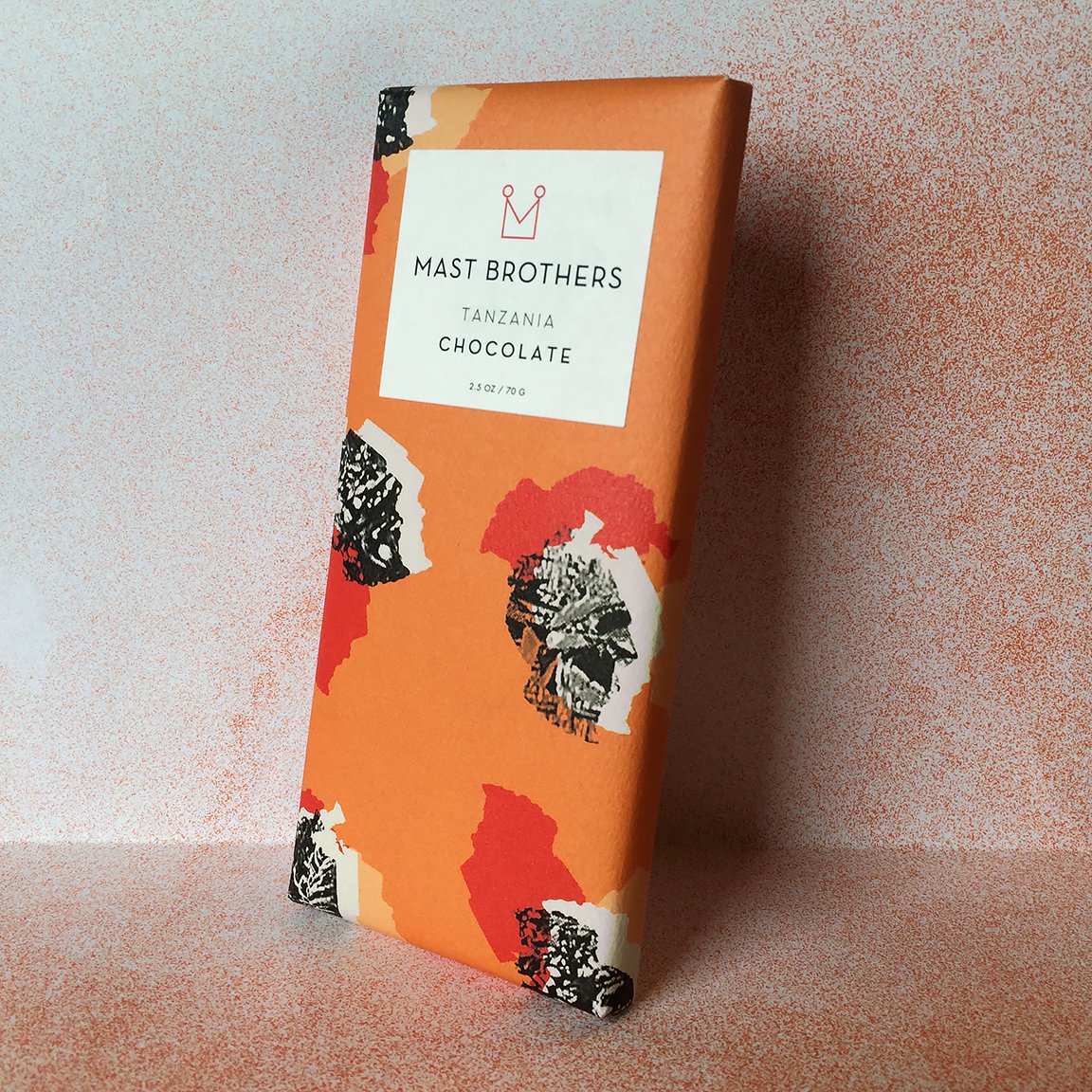

Simran: Someone recently asked me, ‘What have been some inflection points for you, or memorable times in the business?’ One of the times that stuck out was back when Mast first started working with us, they had a number of the single origin bars, and they had this packaging with an orange wrapper and a gray outline of the Tanzanian map. The first time someone sent me a photo of that Mast Tanzania bar, and I saw “Tanzania” printed across the front, that was a pretty surreal moment. Then of course when I got to try the bar and get my paws on it, that was very cool too.

Mast Journal: So compared to the challenges you had when you were starting out, what are the challenges you face now as an established company and name?

Simran: Our biggest challenges have always been infrastructure. In the rains, our roads just wash out. We used to have to drive to the cell phone tower to send an email. Now, thankfully, we have much better connectivity. And capacity-wise, we’ve just outgrown our current facility. So we need to build a new facility, which is the big thing on our plate right now. Also, as you’ve probably heard, global shipping is a bit of a mess right now!

Mast Journal: What do you think the average chocolate eater doesn’t know about cocoa?

Simran: I don’t think people understand just how manual the whole process is. It’s not like agriculture in many parts of the west, with one thousand acre farms of wheat that a computer-operated combine runs by GPS. Cocoa is a small-holder manual crop, where each pod has to be cut off a tree by hand, has to be broken open by hand, and the beans have to be scooped out by hand. Then, they have to be weighed, transported to our facility, lowered into our fermentation boxes, and moved to drying tables. Each day we carry out the drying tables and then back in, and afterwards they’re dried, hand-sorted into each bag, and then they’ll get blended, packaged, then put on a truck and shipped across the world. It’s truly a bean-by-bean manual job.

Mast Journal: Throughout that entire process, what’s the most challenging part to get right?

Simran: For us, it’s the drying because it’s just so weather-dependent. If the weather isn’t cooperating, it can really impact the flavor of the beans and it can also affect the final yield that you’re getting. When the weather gets funky, the beans get funky. Because of our quality standards, sometimes we end up having to throw away more beans than we’d like.

Mast Journal: You’re located in the Udzungwa Mountains National Park. Have you had any memorable wildlife encounters over the years?

Simran: To drive to us, you actually have to drive through a different park. I’ve probably done that drive a couple hundred times — you see giraffes, zebra, elephant, buffalo. Then down where we operate, we’ve seen some big antelope. The last time I was down, I was meeting with our second-largest farmer, and she was telling us that she’s having a big problem with elephants coming into her farm. It’s not so much that they’re eating the cocoa, but they’re passing through the farm and eating the bananas that are growing. Also, when an elephant passes through, it does create a fair bit of destruction. So we’re trying to figure out what we can do to assist with that, without harming the elephants, obviously. We’ve worked with an elephant conservation NGO before, and a farmer’s land is their livelihood. So right now we’re trying to make sure we can mitigate the human-elephant conflict.

Mast Journal: What’s your favorite part about what you do?

Simran: I think we don’t talk enough about the impact we have in terms of job creation in the area. It’s something I’m really proud of. We hire a lot of young people in their twenties, and like I said, even for the older people, it’s often their first official position of employment. To be able to give someone a contract that they can use to get a loan to register for social security and make those payments, that’s all so valuable and it’s something I really enjoy. And of course, being able to see the finished chocolate bar with “Tanzania” on the packaging, or the name of our company, or the name of the area we live in, that’s been very rewarding.

Mast Chocolate Collection, 2022

Every bar is made with organic cocoa beans exclusively from Kokoa Kamili.

Just like family, it’s a special thing to evolve and grow alongside those you've known since the beginning. We heartily thank Kokoa Kamili, their dedicated community of farmers, and everyone they work with to bring us and the world their delicious cocoa.

In the spirit of honoring origins, we’d also like to wish all mothers a very happy early Mother’s Day. Whether you’re a new mother, longtime mother, honorary mother, grandmother, or any one of the many shapes and forms that mothers take, we can’t thank you enough for what you do. Mothers truly make the world go round – and we’re all the better for it.

The Mast Journal

More from The Journal

In conversation with Bellwether’s Head of Sustainability & Impact, Grayson Caldwell.

Read more